Reshaping Supply Chain With AI ML

- Roshini

- Sep 16, 2021

- 4 min read

Where are AI Practices implemented?

How AI helps in optimizing Inventory Management?

The adaptation of AI practices in inventory management is a revolution in the industry, more efficiently preventing depletion of stocks and increasing in stock levels. On an average there are 45 million of orders in a day and would be even more during a Sale Day (like black Friday). In such cases, part on AI and automation for planning the inventory has been significantly efficient and cost saving. So, to summarize this, AI and Machine learning is used in planning stock replenishments, estimating the time taken and safety stock management.

AI and machine learning helps in scaling the inventory optimization across all distribution locations and factors that affect demand and time-to-customer delivery performance with constraint-based algorithms.

Another advanced AI approach using Reinforcement Learning where the models don’t just make predictions but act on these predictions. It’s about giving the model the option to act on what it’s predictions in simple words, the model taking control of the inventory operations, with human checks.

Warehouse management

For any consumer-based company overstocking and understocking can be a disaster, the success of any retail company is heavily reliant on warehouse and inventory management. With demand forecasting, Machine learning provides an endless loop of forecasting, where the outputs are self-improved as new data and business gets added which could reshape warehouse management as we know today.

How does it help in Procurement?

This process usually is seen twice in a supply chain process, initially to acquire the materials/supplies from different suppliers for the business. Then, in delivering the final product to the end users (or distribution of the products). The procurement process involves:

Identifying the requirements

Sourcing

Deciding & finalizing the terms and price

Ordering and Purchase requisition

Delivery

Supply and Inspection

Transaction, payment process

Maintaining the data

Review & feedback

AI makes the process in each step in different ways like analyzing a cost saving and efficient process which is called procurement analytics and using chatbots or AI assistance for trivial conversations, sending actions regarding compliance and governance requirements, placing order/purchase requests, learn and answer questions regarding procurement functionalities, documentation of invoices and payments/order requests.

How and where can AI make a difference in Logistics/ Transportation?

Logistics is a separate wide process which involves planning and implementation of effective forward and reverse flow of Storage of goods/services from the point of origin to point of consumption helping to tackle the complex traffic patterns and transportation of the goods, shipping and receiving, import and export operations, warehousing, inventory management, purchasing, production planning, and customer service. Here, we are specifically looking at transportation as part of the supply chain process. AI has been a talk of town for the past few years as it brings accurate and faster shipping reducing the lead times and more cost cutting in transportation expenses, labor costs also environment friendly.

In the recent years, the idea of Autonomous vehicles for logistics and shipping was widely spoken, researchers say that this would bring astronomical impact in Logistics optimization but how resilient is the physical-flow and network is to adapt to such huge shift is a matter of doubt.

Apparently, Rolls Royce, the famous car company for luxuries cars are creating autonomous Vehicles. If you are thinking it is autonomous cars… No, they are creating autonomous ships. Currently AI algorithms are used to identify if there are any objects around in water using sensors and classify them according to the risk and how dangerous they can be to the ship. The future developments will include functionalities like tracking ship engine performance using sensors, loading, and unloading and security monitoring. This upgradation in ships of being aware of what is around them makes shipments faster and safer. Situations like losing ships due to bad weather or by running into dangerous items can be avoided, which means goods can cross oceans faster and easier.

What is Predictive Analytics?

Predictive analytics is the method with which valuable, hidden, and useful insights are derived from the massive data collected in the supply chain process.

For example, the data collected in surveillance cameras in warehouses and stores which are regularly used to monitor stock levels and to give alerts when restocking is required. The same data can also be used to forecast and estimate when a resupply will be required which is called inventory management. This also includes making business strategy from the insights and for reduce cost with demand and supply with analysis.

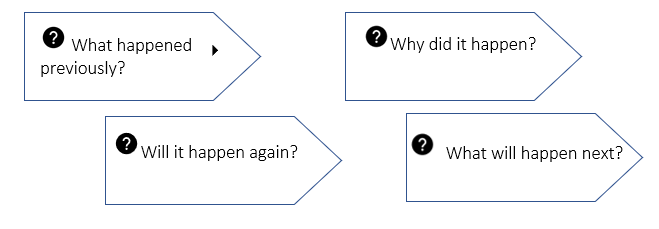

To put it simple, predictive analytics is done knowing, understanding the data by finding answers for questions like,

One of the good examples of demand and supply system with the predictive analytics done on the data acquired, reducing the transport cost is the case of Coca cola vending analytics. Where they analyze the data (number of tins taken) based on each area, each vending machine to find the demand for the drink in each vending machine estimating the right frequency or time and numbers to loads required for the tins in each vending machine. This way they reduced the transport cost for refilling.

Hope that gave you a brief on supply chain process and how it is evolving with Machine Learning and Deep Learning. We’ll explore more with a sample dataset in our future blogs.

Till then, Jump in deeper with Deep Learning - Neural networks and Machine Learning.

Stay Tuned for more freaky news and facts. Feel free to share your thoughts in the comment section and do check our other posts on cyber and AI here.

Follow us on Instagram for the latest updates in Cybersecurity and AI.

You can find me on LinkedIn

Comments